Hi Chaps

I trust everyone had a good Christmas and received lots of interesting stuff from Santa?

My wife and I decided not to go too mad this year, as with a baby due in about 4 weeks time, pushchairs, car seats and nursery furniture need to take priority! Having said that, I did get a couple of good books ? The Heyday of the Hydraulics, by Hugh Dady and In the Tracks of the ?ACE?, by Jeffery Grayer and I can thoroughly recommend both titles!

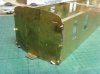

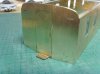

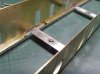

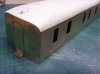

This morning, I woke up and assumed I?d be getting stuck in to some more decorating, but my wife said ?You can?t do DIY on Boxing Day - do some modelling instead?. I didn?t have to be asked twice, so I thought I?d take another look at the Hawksworth and see what could be done.

For starters, I decided to get the ?B? end up to the same stage as the previously done ?A? end?.

. The Hawksworth Brake looks the business

. The Hawksworth Brake looks the business  . Looking forward to the progress reports

. Looking forward to the progress reports

. The Hawksworth Brake looks the business

. The Hawksworth Brake looks the business  . Looking forward to the progress reports

. Looking forward to the progress reports