Ian@StEnochs

Western Thunderer

Herbie I could not ask for a more useful photo of the cab interior. I expected to find 564 at Weybourne shed last August but she was in steam with a busy crew and this shot wasn't possible. I am treating the cab interior as a separate model to do after the rest of the model is built and painted and if you have other footplate shots you could append them to the Gallery topic, this had been more popular than I expected:

Prototype - Ex-GER Y14 (LNER J15) preserved at the North Norfolk Railway

Back to the build, yesterday's efforts are getting down into the noise floor but they have to be done. I have stripped out all of the electrics and dealt with most of the missing details on the tender . . .

- -

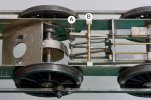

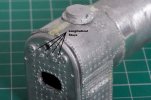

Rear handrails.View attachment 182555

The original rear handrails (last October) broke off a couple of times so I have tried for a stronger fixing. This is microbore brass tube by Albion Alloys, 1.1 mm OD and 0.9mm ID fixed into the body with 188 degree solder paint.

View attachment 182556

Then trimmed flush to make a socket.

View attachment 182557

The handrail wire is 0.7 mm diameter so there is room for the glue to hold them into their sockets after painting.

Good solution Richard. I do similar as most of my locos have bright metal handrails. I try to solder the tube from the inside before fitting the top. I have been using 1/0.5 tube and open the bore out once soldered in. A lot of handrails had a boss which butts up against the plate with a nut and washer on the other side. If the tube is left slightly proud it represents that boss.

Ian.