I don't regard the regular derailments at Kettering as a failure. I want my trains to run on 0-MF track down to the radius of a B6, slightly tightened by setting the turnout on a curve to make the trackwork look better. Anything tighter than this is a bonus, but being able to negotiate a sideways step in the rails at a baseboard joint isn't part of the brief.

The Y14 and its tender are the largest stock I possess. So far, I have seen them separately negotiate my Peco Setrack turnout, where the curved gauge drops to around 31.3 mm, and a reverse curve beyond this added using Setrack. The loco lost its ability to run through the turnout when I removed the free play on the middle axle, but still manages the 32 mm Setrack curve.

Adding the close coupling between loco and tender has removed the ability for the pair to run on the Setrack curve, but I don't really mind. I want a loco which looks as realistic as I can manage, and having an enlarged gap between loco and tender will rather spoil things.

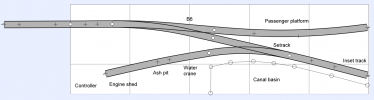

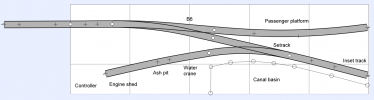

This scheme would be a combination of test track, photographic diorama and a first attempt at scenics in 7mm scale.

Fundamentally, the track can challenge a specimen loco or wagon to a series of defined criteria. The track at the back is 31.5 mm gauge, the rest is 32 mm with the B6 tapering to make the transition. I imagine a DPDT switch to let me switch the two frogs from being live to dead. I have space for a 16 inch traverser to the left.

I would call this "Heybridge Basin". I think I have outgrown my present test track so any thoughts on this new one, either as a test track or as a layout, would be very welcome.