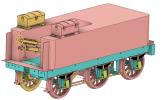

The loco has now gone to the paint shop, where it will be for some time because painting isn't my favourite task and I'll happily take any excuse to do something else. The present excuse is that bits for the tender have arrived and are just asking to be worked on.

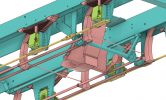

The wheels, as before, have 3D printed nylon centres. Previously, I made the tyres for the loco wheels from some large diameter steel bar. This time I got blanks laser cut in steel. It actually worked out roughly the same price (large diameter bar isn't cheap) and should be quicker to cut because there is much less material to bore out from the centre.

So why so many wheels? Well, I decided to get enough parts for two tenders. The LNWR must have built lots of these tenders because I've seen photos of them trundling around behind many different classes - so I have options for future (undefined) projects. I might even build two because it's usually quicker to build together rather than one after another. I also needed a new wheelset for the loco to replace the existing one that has the wrong number of spokes (oops), and I added a few more just because. Actually I think I got a price break on either the centres or the blanks. It's worth seeing where this cuts in when placing an order.

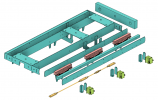

Along with the tyres, I ordered the steel parts for the tender frames. Again there's enough for two tenders. When I get bored of turning tyres I can start assembling this lot.

Nick