Richard Gawler

Western Thunderer

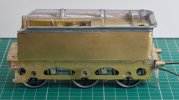

I have made a start on the chassis for the tender so I can get an idea of how the finished model is going to look. This is the third sub assembly for the model.

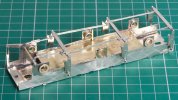

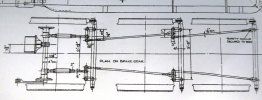

The chassis is a “model chassis” (I mean, not a prototypical chassis) in that it sets the wheels running in internal not external bearings. Nevertheless I have tried to make the result look a bit less unrealistic by shortening the frame spaces so they don’t extend below the axles. I have used two of the four frame spaces provided in the kit and put a strip of brass along the bottom of the frames to keep the assembly rigid.

The kit builds up into a rigid chassis with the middle axle set about 1/4 mm higher than the other two. I managed to lose most of this 1/4 mm when I opened up the holes in the frames to accept the wheel bearings, so suitably inspired by work elsewhere on WT I have elongated the holes and provided some springs from phosphor bronze wire, 0.5 mm diameter. The design of these springs was a total guess but they seem to work fine. The wheels have movement of about 0.5 mm downwards and most of 1 mm upwards, probably more than they really need.

I am pleased with the appearance of the brake blocks. The loco will not have brakes so I used the brake blocks supplied for the loco as packing underneath the brake blocks for the tender. I think this gives the brake blocks a bit more depth and they look as though they are separate parts and not just stamped out as one piece with the hangers.

The partition across the width of the chassis makes a compartment at the front to hold a piece of lead. The idea is to shift the centre of gravity forwards; otherwise, almost all of the weight of the tender is coming from the battery pack sitting above the rear axle. I realise that 7mm of lead may well ruin the performance of the radio receiver above it but I can only try and see how well things work out. I could put some lead into the sides of the body near the front instead. I am rather hoping the receiver will receive all the radio waves it needs through the holes and slots above its on-board aerial.

The chassis is a “model chassis” (I mean, not a prototypical chassis) in that it sets the wheels running in internal not external bearings. Nevertheless I have tried to make the result look a bit less unrealistic by shortening the frame spaces so they don’t extend below the axles. I have used two of the four frame spaces provided in the kit and put a strip of brass along the bottom of the frames to keep the assembly rigid.

The kit builds up into a rigid chassis with the middle axle set about 1/4 mm higher than the other two. I managed to lose most of this 1/4 mm when I opened up the holes in the frames to accept the wheel bearings, so suitably inspired by work elsewhere on WT I have elongated the holes and provided some springs from phosphor bronze wire, 0.5 mm diameter. The design of these springs was a total guess but they seem to work fine. The wheels have movement of about 0.5 mm downwards and most of 1 mm upwards, probably more than they really need.

I am pleased with the appearance of the brake blocks. The loco will not have brakes so I used the brake blocks supplied for the loco as packing underneath the brake blocks for the tender. I think this gives the brake blocks a bit more depth and they look as though they are separate parts and not just stamped out as one piece with the hangers.

The partition across the width of the chassis makes a compartment at the front to hold a piece of lead. The idea is to shift the centre of gravity forwards; otherwise, almost all of the weight of the tender is coming from the battery pack sitting above the rear axle. I realise that 7mm of lead may well ruin the performance of the radio receiver above it but I can only try and see how well things work out. I could put some lead into the sides of the body near the front instead. I am rather hoping the receiver will receive all the radio waves it needs through the holes and slots above its on-board aerial.