Back to bogies - adding detail

Heather Kay

Western Thunderer

Sorry for the gap in comms. You can guess why.

Anyway, thanks for all the input on the grab rails. I think I’ll go with fixing the wire rails in place before painting gets started, then just paint them a sort of darkish brownish sort of colour and be done.

Meanwhile…

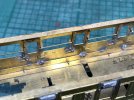

I have begun to face down the daunting task of detailing these beggars. So far, it’s soldering in the whitemetal castings for the bolster springs. Next, I think it’s opening all the spring damper bracket holes a gnat's crotchet. After that, carefully separating the printed parts and just getting down to gluing them together.

No doubt, I shall be some time.

Anyway, thanks for all the input on the grab rails. I think I’ll go with fixing the wire rails in place before painting gets started, then just paint them a sort of darkish brownish sort of colour and be done.

Meanwhile…

I have begun to face down the daunting task of detailing these beggars. So far, it’s soldering in the whitemetal castings for the bolster springs. Next, I think it’s opening all the spring damper bracket holes a gnat's crotchet. After that, carefully separating the printed parts and just getting down to gluing them together.

No doubt, I shall be some time.