Jon Nazareth

Western Thunderer

This is a project started by some members of the G3 Society with the idea of making available a loco kit at a reasonable cost to members and would be members of the Society. If you are interested and feel like coming over to the other side drop a line to, g3projectloco@gmail.com. Michael will be able to answer all of your questions.

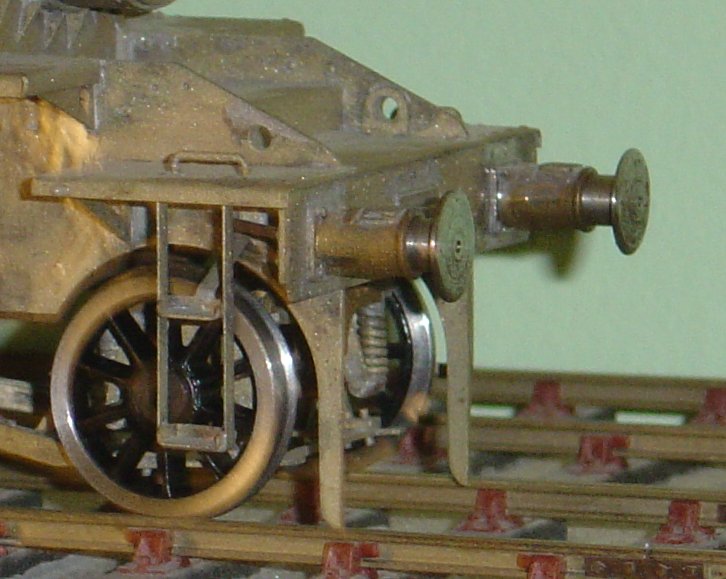

I wasn't going to start my G6 until after I had finished Jennifer Who. However, I messed up the machining of the driving wheels and had to order replacements from Mark Wood which left me with some modelling time on my hands. At the moment, I'm only skirting around the edges of the kit, cleaning up some of the pieces and progressing little jobs. In the picture are the safety chains yes, she carried safety chains. Yes, she carried safety chains when first commissioned and I'm including them on my engine. I do like safety chains. I also made up the coupling rods as you can see here. They are not fluted as supplied and it's a shame that they are not as they would have looked much nicer if they had been. The idea was to keep costs down hence the lack. Once my new wheels arrive, I shall go back to Jennifer Who but in the meantime, I'll keep nibbling away here.

Jon

I wasn't going to start my G6 until after I had finished Jennifer Who. However, I messed up the machining of the driving wheels and had to order replacements from Mark Wood which left me with some modelling time on my hands. At the moment, I'm only skirting around the edges of the kit, cleaning up some of the pieces and progressing little jobs. In the picture are the safety chains yes, she carried safety chains. Yes, she carried safety chains when first commissioned and I'm including them on my engine. I do like safety chains. I also made up the coupling rods as you can see here. They are not fluted as supplied and it's a shame that they are not as they would have looked much nicer if they had been. The idea was to keep costs down hence the lack. Once my new wheels arrive, I shall go back to Jennifer Who but in the meantime, I'll keep nibbling away here.

Jon