AdamF

Western Thunderer

Finally, my workbench is under way

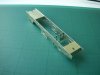

Parts for my JLTRT Class 517 tank have arrived, the prototype has been chosen (talk about a confusing class of loco ???) and I am ready to go!

However, perhaps unusually, my thread begins with a couple of questions...

1) how to compensate/spring the chassis. The instructions seem to go for fixed driving axles and compensated trailing axle. I'm wondering whether to spring the front driving axle as well - any thoughts?

2) is it best to get the wheels turned down to Scale7 standards prior to commencing the build? I only ask as I have read that they can rust when exposed to flux and I anticipate having to use the wheels from time to time to calibrate various chassis fittings etc. for soldering into position so was wondering whether I could do that first, complete the chassis and then send the wheels for turning down.

3) any ideas on a very small but powerful and smooth motor and gearset?

Any help on the above gratefully received!

A

Parts for my JLTRT Class 517 tank have arrived, the prototype has been chosen (talk about a confusing class of loco ???) and I am ready to go!

However, perhaps unusually, my thread begins with a couple of questions...

1) how to compensate/spring the chassis. The instructions seem to go for fixed driving axles and compensated trailing axle. I'm wondering whether to spring the front driving axle as well - any thoughts?

2) is it best to get the wheels turned down to Scale7 standards prior to commencing the build? I only ask as I have read that they can rust when exposed to flux and I anticipate having to use the wheels from time to time to calibrate various chassis fittings etc. for soldering into position so was wondering whether I could do that first, complete the chassis and then send the wheels for turning down.

3) any ideas on a very small but powerful and smooth motor and gearset?

Any help on the above gratefully received!

A

No? Oops, sorry 'bout that...

No? Oops, sorry 'bout that...

- I'm not very good with a camera, though I have a feeling that the hobby will become as much about the photography as the modelling

- I'm not very good with a camera, though I have a feeling that the hobby will become as much about the photography as the modelling

That'll teach me to check before working!

That'll teach me to check before working!