My main niggling worry with Lightburn is that I had picked up on digging through Internet that placing kerf offsets might not be straightforward and that Lightburn tends to place them as it saw fit, which is not what I wanted. Also you couldn't see beforehand on which side of a line the offset was. With Cut2D I can place a kerf offset for any part of a drawing and can also see and check where the cut is placed before I send the file to the laser cutter. I'll maybe now do some checking with Lightburn to see how their offset placing works.

Kerf offset is easy to tweak (although 3 decimal places might be overkill):—

Positive kerf is outside the shape & negative inside. Measuring the kerf with a set of feeler gauges will give a start point

The other smaller consideration is that Cut2D imports DWG files whereas Lightburn only imports DXF files, and when it imports these files, it places them in the centre of the working area and not with reference to the original placement in the CAD file. I do all my 2D designing in AutoCAD 2D or one of its clones, so direct import of DWG files is a plus point.

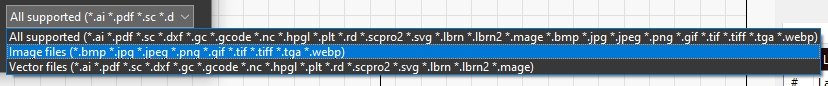

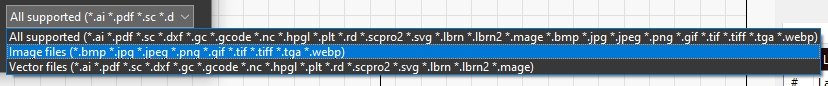

I use Illustrator CS6, & Lightburn will import the outlines directly. It ignores any live fonts & effects though. Current importable formats:—

I'll probably dig around a bit more with Lightburn to see how it performs and have a look in more detail on how it deals with kerf offsets. I do like some of its features, like the Material Test application which is really handy for assessing cuts or etches for new materials.

So I've got both pieces of software on the HP laptop which works with the laser cutter and both will probably get used.

Jim

I tried it on spec & after about a week of using it happily dropped £50 on it to get a full licence. I found it to be very intuitive, although I wouldn't use its drawing tools for anything complex - quite happy with Illustrator for that.

Lightburn are set to introduce a new program called MillMage that'll cater to grbl-driven Spindles. If it's as straightforward as LB, I'll have that too. I'm currently using EstlCam, which is OK, but I'm not enamoured by it - I find it a bit crashy.

Pete S.

) so searching for Version 5 tutorials could get you more.

) so searching for Version 5 tutorials could get you more.

- as I type. Best Beloved still isn’t well, but he’s definitely been improving this past few weeks.

- as I type. Best Beloved still isn’t well, but he’s definitely been improving this past few weeks.