davey4270

Western Thunderer

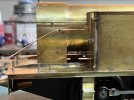

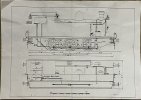

I am in the process of building a 7mm model from an ancient Gateneal kit of the above locomotive. I know of only 3 photographs of this rather camera shy specimen and hope there are some more out there to help detail this poor quality and inaccurate model. The 3 pics I have are at Bury Port in L&MMR days, early GWR at Duffryn yard and later GWR with the roundel at Neath N&B.

Any further views would assist with detailing, particularly a rear view or a tank top view which would answer the question of if the space between the tank tops and the boiler was covered to prevent water ingress to the motion as on most GWR side tanks. A lot of pre grouping Welsh Railway locomotives didn't have this feature.

Thanks in advance,

David.

Any further views would assist with detailing, particularly a rear view or a tank top view which would answer the question of if the space between the tank tops and the boiler was covered to prevent water ingress to the motion as on most GWR side tanks. A lot of pre grouping Welsh Railway locomotives didn't have this feature.

Thanks in advance,

David.